About XPS building boards

The strength-to-weight ratio of our XPS, STYRISOL®, is impressive and the cell structure is designed to withstand compression even under the most demanding conditions.

This makes XPS the perfect choice for insulation applications where durability is a requirement.

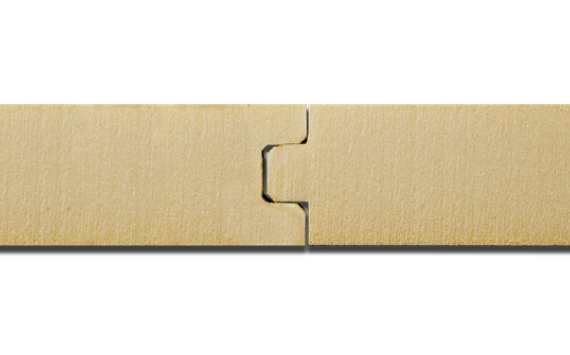

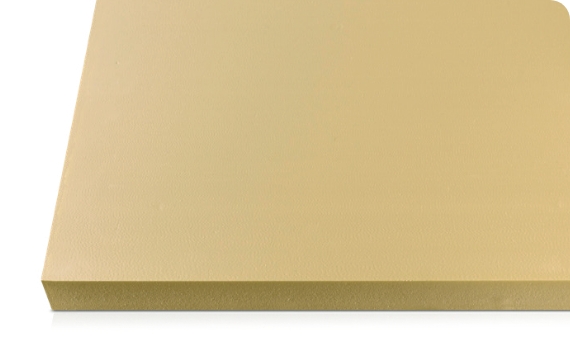

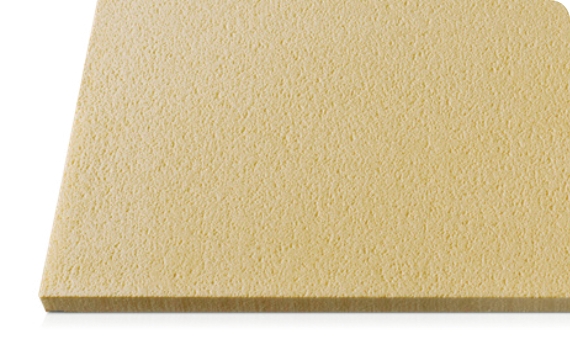

Abriso Jiffy’s XPS boards are available in different sizes and different surface textures and edge finishes.

These boards are used to insulate roofs, cellars, walls and even swimming pools.

Properties:

100 % recyclable

High thermal resistance

High compressive strength

Non-perishable

Resistant to fungus, microbes, vermin and rodents

Self-extinguishing additive

Available specifications:

from 20 mm to 200 mm

from 500 mm to 650 mm

from 1200 mm to 3200 mm

Available edge finishing:

Available surface:

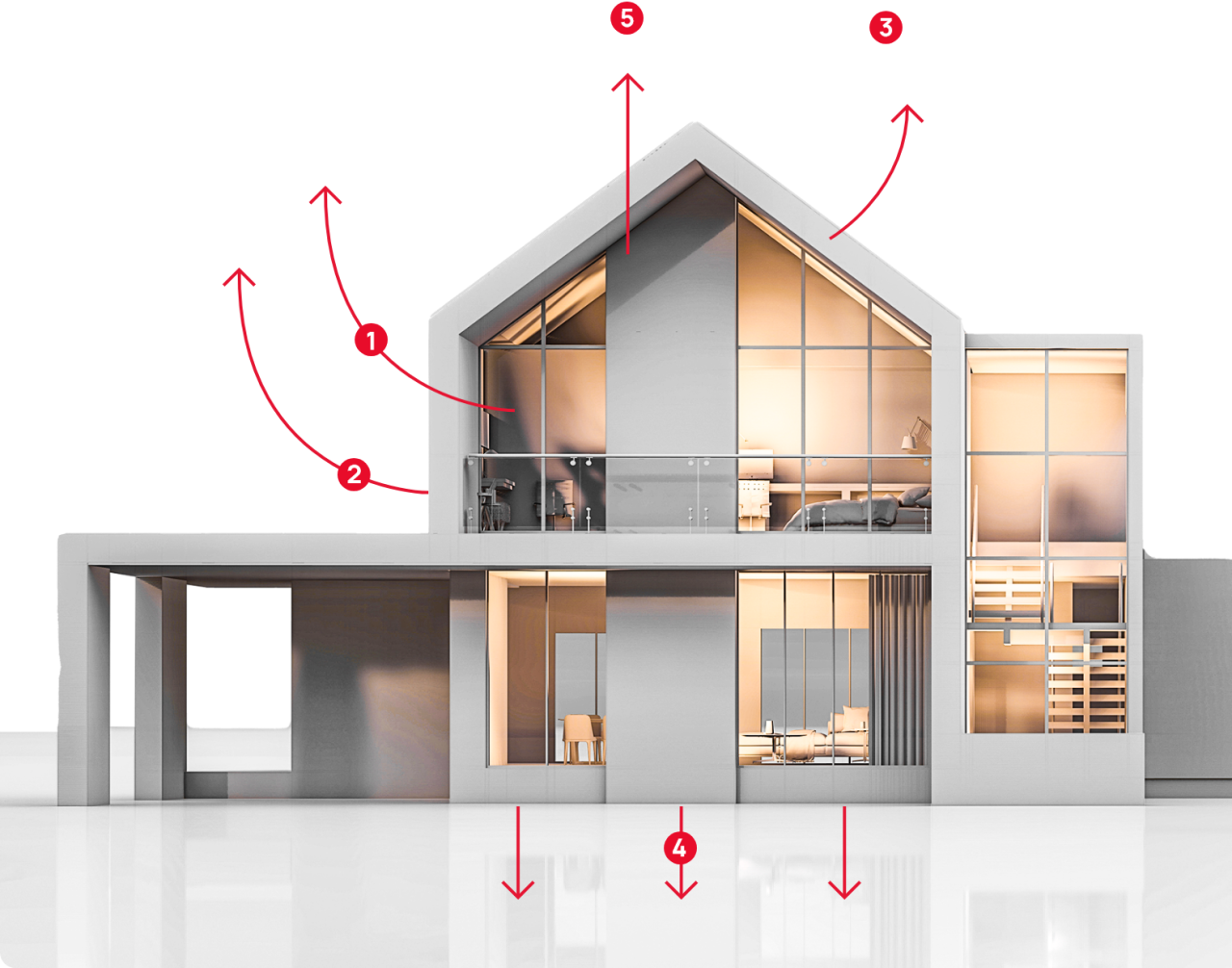

Application of our products:

STYRISOL® XPS boards from Abriso Jiffy are the ideal choice for insulation applications where a long service life is an unavoidable requirement.

Our XPS boards are available in different densities, sizes, surface textures and edge finishes to perfectly suit any project.

Whether you are insulating walls, roofs, cellars or other spaces, you can always rely on STYRISOL® XPS boards.

Sustainability and energy efficiency

XPS is not only sustainable over time but also for the environment. It lasts a long time, reduces energy consumption and CO2 emissions. STYRISOL® is perfectly recyclable.

Even Abriso Jiffy’s production process is 100% committed to reusing internal XPS residual waste.

This makes our XPS, STYRISOL®, the green choice for a more efficient, sustainable future.

Thermal loss:

- windows & doors 19 %

- walls 37 %

- roofs 13 %

- floors 11 %

- ventilation 20 %